Bekannter adopts paperless office, office automation OA system, daily application and approval can be completed quickly and conveniently, work efficiency has been greatly improved. At the same time, we regularly comb the process, simplify and update, to provide the practicality of the process

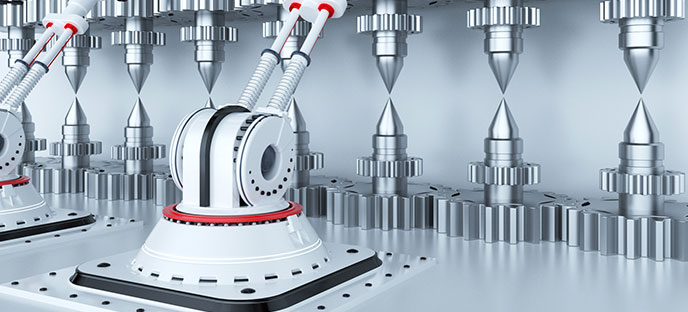

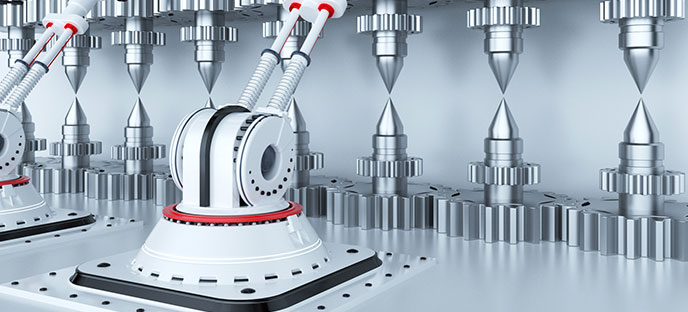

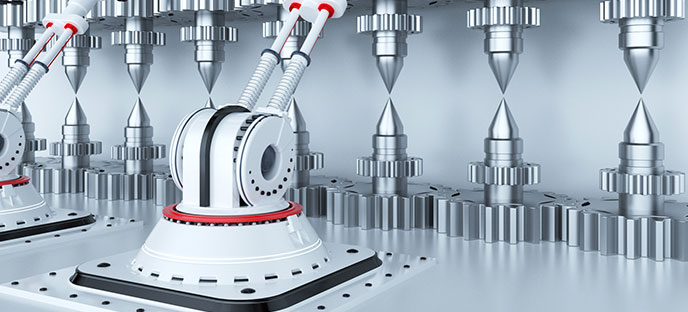

The company currently has more than 80 professional mechanical design and manufacturing personnel, committed to providing customers with ultra-precision parts design and machining solutions. The company has a sound production process system, on-site 5S management and quality management system, and has passed the CE-EU quality certification, GB/ T19001-2016/ISO9001:2015 quality management system, GB/T24001-2016 IDT ISO14001:2015 environmental management system, GB/T28001-2011 IDT OHSAS 18001:2007 occupational Health and safety management system and other certifications.

Headquarters Bekannter robot technology co., LTD. Is a collection of industrial robot ontology research and development with high speed and high precision automation integration solutions provide for the integration of high-tech enterprises, is the only global company with parallel robot, a full range of enterprise products in the food and beverage, pharmaceutical/health care products, logistics, automobile, chemical, 3 c and new energy industry of material, production assembly, sorting, packaging stacking precision measurement and precision positioning, torque sensors, medical equipment, the respect such as motion simulation is widely used.

Bekannter adopts advanced ERP and CAM manufacturing resource management system to realize synchronous monitoring and management of manufacturing process. At the same time, the warehouse bar code management system is deeply implemented to efficiently and orderly manage the factory and warehouse. It has passed the CE-EU quality certification, GB/ T19001-2016/ISO9001:2015 quality management system, GB/T24001-2016 IDT ISO14001:2015 environmental management system, GB/T28001-2011 IDT OHSAS 18001:2007 occupational Health and safety management system and other certifications.

-

OA office system

OA office system

Bekannter adopts paperless office, office automation OA system, daily application and approval can be completed quickly and conveniently, work efficiency has been greatly improved. At the same time, we regularly comb the process, simplify and update, to provide the practicality of the process

-

Warehouse bar code management system

Warehouse bar code management system

Warehouse bar code logistics management system is based on the advanced bar code technology.

The whole machine is imported with original package, positioning accuracy 5 m, repeated positioning accuracy 3 m, processing stroke of the equipment: 1,330 *762*700, the equipment has 0.1 m feed and 1 m cutting ability, can meet the processing requirements of high precision products such as optical molds.

Fast and accurate digital data transfer technology can process high precision and high response speed in real time.

Machine imported from, these NEX108 mainly depend on the maximum speed of 5000 RPM, equipped with high precision, high speed knife tower server. Maximum radius of 320 mm, maximum processing length of 481 mm, can be cylindrical workpieces, spherical work-piece, artifacts, sector, special-shaped non-standard parts, etc., the workpiece can be a card is completed, accuracy is higher than ordinary numerical control lathe.

The whole machine is imported with original package, positioning accuracy 5 m, repeated positioning accuracy 3 m, processing stroke of the equipment: 1,330 *762*700, the equipment has 0.1 m feed and 1 m cutting ability, can meet the processing requirements of high precision products such as optical molds.

Fast and accurate digital data transfer technology can process high precision and high response speed in real time.

Machine imported from, these NEX108 mainly depend on the maximum speed of 5000 RPM, equipped with high precision, high speed knife tower server. Maximum radius of 320 mm, maximum processing length of 481 mm, can be cylindrical workpieces, spherical work-piece, artifacts, sector, special-shaped non-standard parts, etc., the workpiece can be a card is completed, accuracy is higher than ordinary numerical control lathe.

The whole machine is imported with original package, positioning accuracy 5 m, repeated positioning accuracy 3 m, processing stroke of the equipment: 1,330 *762*700, the equipment has 0.1 m feed and 1 m cutting ability, can meet the processing requirements of high precision products such as optical molds.

Fast and accurate digital data transfer technology can process high precision and high response speed in real time.

Machine imported from, these NEX108 mainly depend on the maximum speed of 5000 RPM, equipped with high precision, high speed knife tower server. Maximum radius of 320 mm, maximum processing length of 481 mm, can be cylindrical workpieces, spherical work-piece, artifacts, sector, special-shaped non-standard parts, etc., the workpiece can be a card is completed, accuracy is higher than ordinary numerical control lathe.