The phone:400-082-0829

email:info@bekannter.cn

Address: Building 3, Phase II, Thousand Talents Planning Industrial Park, Yuyao, Ningbo, Zhejiang

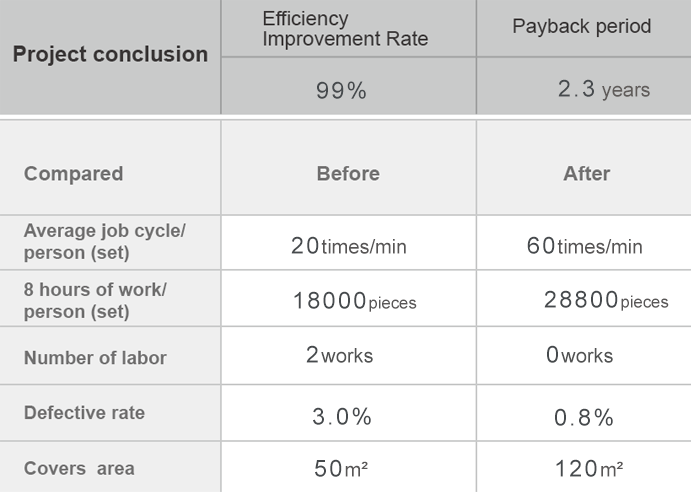

1. There are as many as 15 kinds of workpiece, 15 specifications are Shared, and the product identification position is small, which requires high visual recognition in sorting.

2. In the sorting process, unqualified products should be eliminated in time, and the balance between accuracy and speed is strictly required.

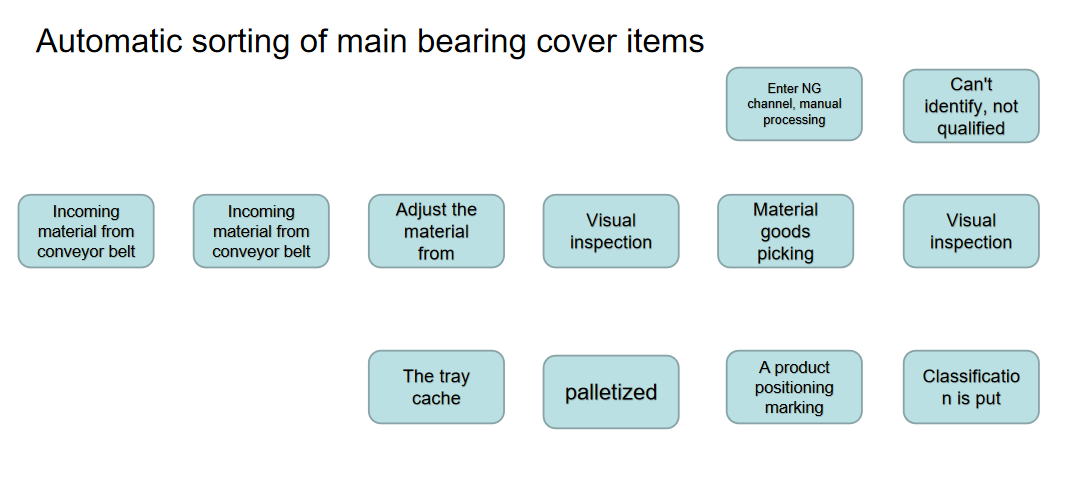

A scraper is added to the incoming material conveyor belt to prevent the workpiece from lamination. After the visual position detection system, the material handling robot grabs the workpiece and puts it neatly. The workpiece passes through the laser visual detection system in turn to identify the type of the workpiece