The phone:400-082-0829

email:info@bekannter.cn

Address: Building 3, Phase II, Thousand Talents Planning Industrial Park, Yuyao, Ningbo, Zhejiang

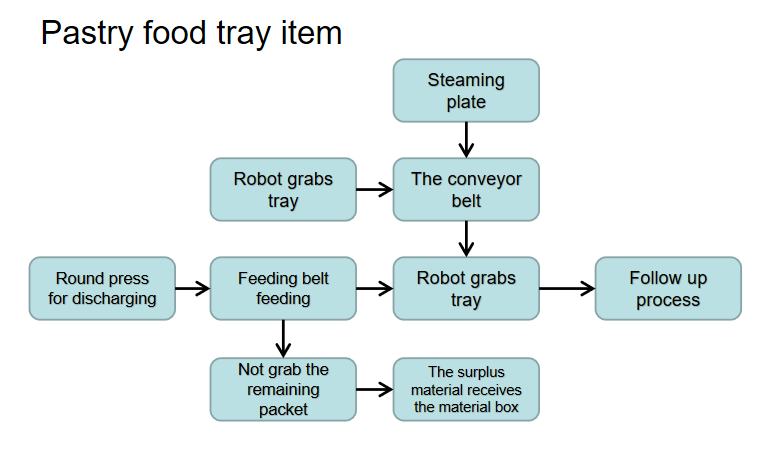

First, grasp the process of baozi deformation

Second, the spacing of the mounting should be kept even

Empty tower plate via return conveyor belt transmission to rise, waiting for again to grab station, round charter flights out of the green, the steamed stuffed bun after flower machine embossing, by ring machine will be into the same amount of space between green, TD - 800 [2] disposable fixed-point grab 12 green fixed plate, the plate process is divided into lines to hardback and paperback, hardcover line of TD - 800 [2] before scraping of the green, first the paper into the empty plate fixed position, then put green in empty tower, paperback line directly placed born bad in empty plate fixed position, and filled with steaming plate will be transmitted to the next working procedure

Among them, the production line is equipped with a total of 1 td-800 [2] robot, which is set in the link of placing the plate in the hardcover. The accuracy of the position of the plate directly affects the final quality of the product