The phone:400-082-0829

email:info@bekannter.cn

Address: Building 3, Phase II, Thousand Talents Planning Industrial Park, Yuyao, Ningbo, Zhejiang

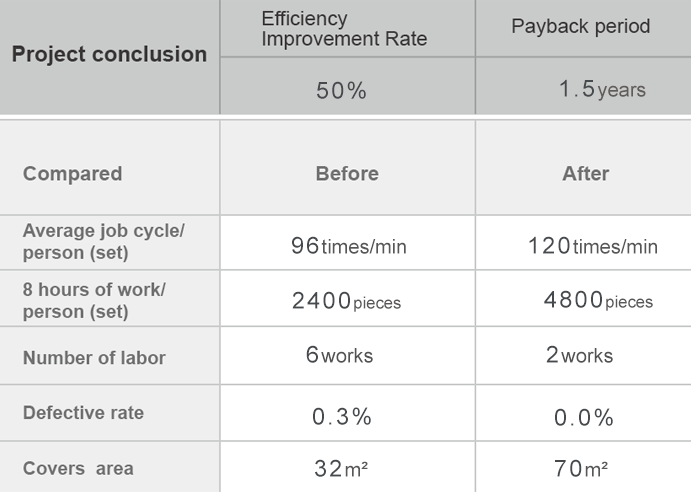

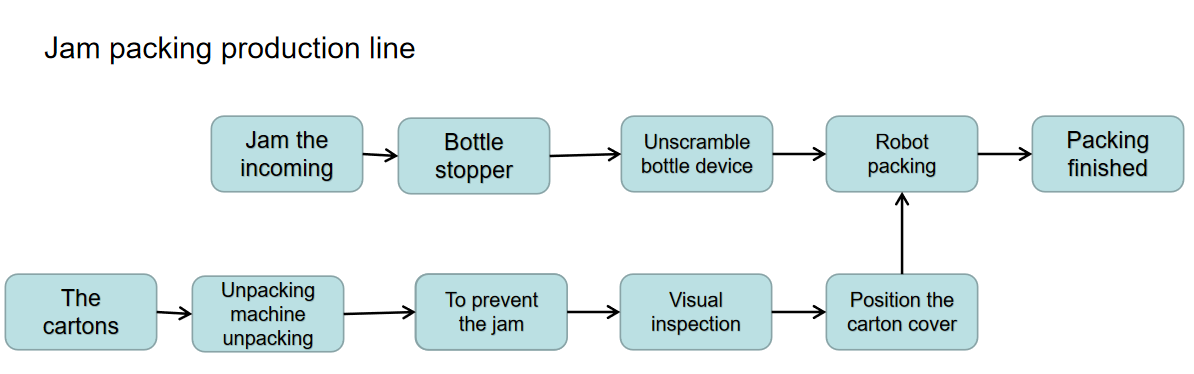

In the process of jam packing, the customer needs to put a single jar of jam weighing 500g into a carton with a middle clamps, and put 96 bottles per minute. The production speed is fast, the labor intensity is high, and the repetitive action is easy to fatigue. There are altogether 6 people in this station, among which 1 person opens the box, 1 person puts in the carton, 4 people pack the box; In the process of workers' rest, the front production line will stop, affecting the production efficiency; Due to the product sales season, the peak season of the staff tension, need to work overtime, off-season workers are relatively idle, resulting in the waste of human resources, increasing the cost of the enterprise

After the product passes through the labeling machine, it flows to the robot working area. First of all, the inverted bottle device is tested. After the bottle sorting device, it is arranged into a row of 4 bottles. The robot installs a special fixture to grab 4 bottles each time, a box of 12 bottles, and each box is grabbed 3 times. The cartons with clamps are transported to the robot's packing position through the conveyor belt. The packing position is provided with a carton positioning mechanism and a carton support mechanism. The carton positioning mechanism can start packing the robot with special clamps