The phone:400-082-0829

email:info@bekannter.cn

Address: Building 3, Phase II, Thousand Talents Planning Industrial Park, Yuyao, Ningbo, Zhejiang

First, the robot should be able to realize the speed tracking of incoming materials and the speed tracking of removing materials, so as to achieve accurate paste

Second, the glue trajectory accuracy requirements are high

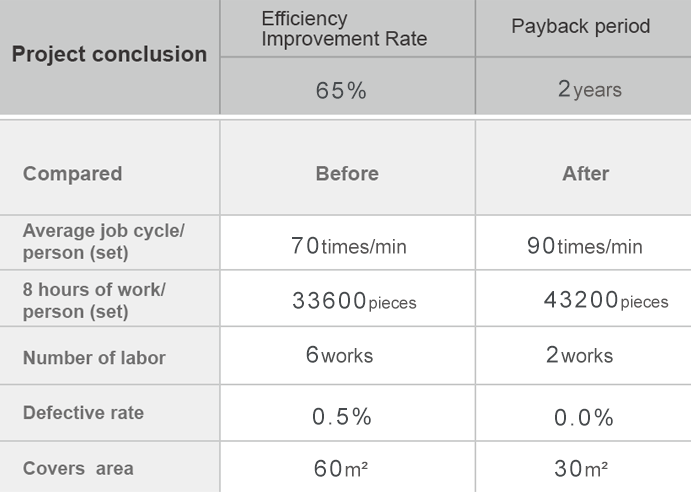

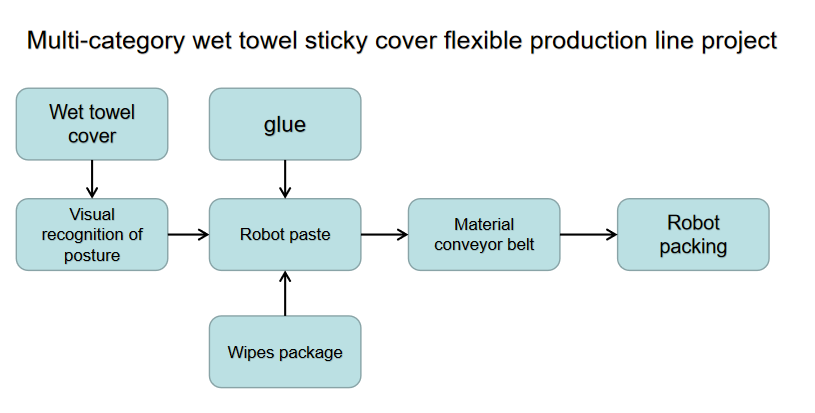

Wet towel cover and the packing bag of some tissues respectively through two incoming conveyors to corresponding visual area is used to identify the position, configuration in two of the encoder on the conveyor belt track incoming speed, visual judgment incoming posture and belongs to the category, information transmission to Polyhedron parallel robot - 1200, parallel robot grab wet towel cover glue in out of the gate, and then paste to the wet towel bags, speed to the beat of up to 90 bags/min

The wet towel packages with a good wet towel cover are arranged neatly into the packing area of parallel robot td-1200 [3] after they are processed in the conveyor belt transmission process. The robot grabs multiple packages of paper towels at the same time and then puts them into one packing, and finally finishes the automatic packing at the end.

In order to make it easier for customers to control the operating system and speed up the system update and debugging between different batches, the parallel robot polyhedron-1200 supports the function of gluing track CAD import and can easily and quickly replace the gluing track