The phone:400-082-0829

email:info@bekannter.cn

Address: Building 3, Phase II, Thousand Talents Planning Industrial Park, Yuyao, Ningbo, Zhejiang

1. Large amount of material is discharged from the front end, and high sorting speed is required for subsequent sorting according to quality

2. The sorting gripper shall meet the sanitation requirements for food handling

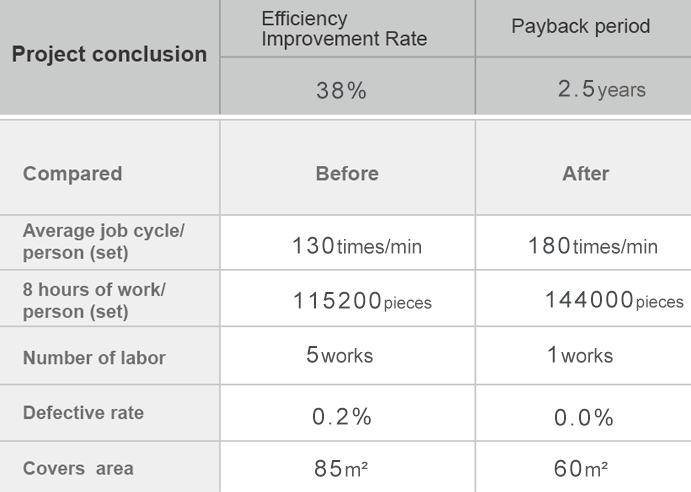

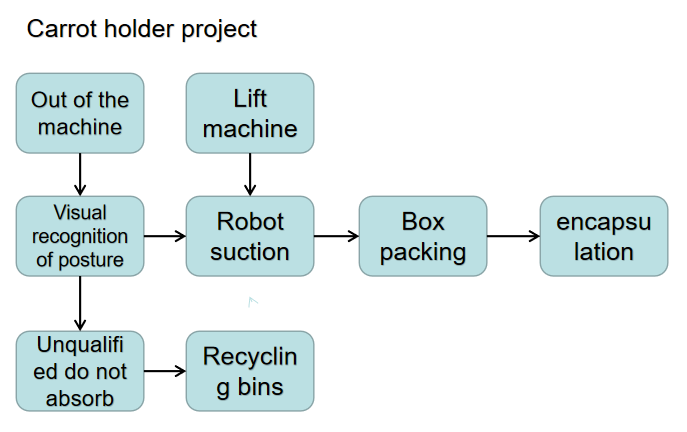

Carrot slices by three discharging equipment discharge at the same time, the manager feeding conveyor belt to the visual system identification outline and position information, Polyhedron - 1200 [4] according to this information, in turn, absorb the carrot slices, quickly placed on the Tory machine processing good box, after waiting for the entire supporting box filled with, sent to the sealing packaging box area, such as incoming material shape is unqualified, the robot will not be processing, finally in the conveyor belt is not cracking down to recycling bins

The production line used a robot to complete the quality of carrot slices sorting and loading two processes